-40%

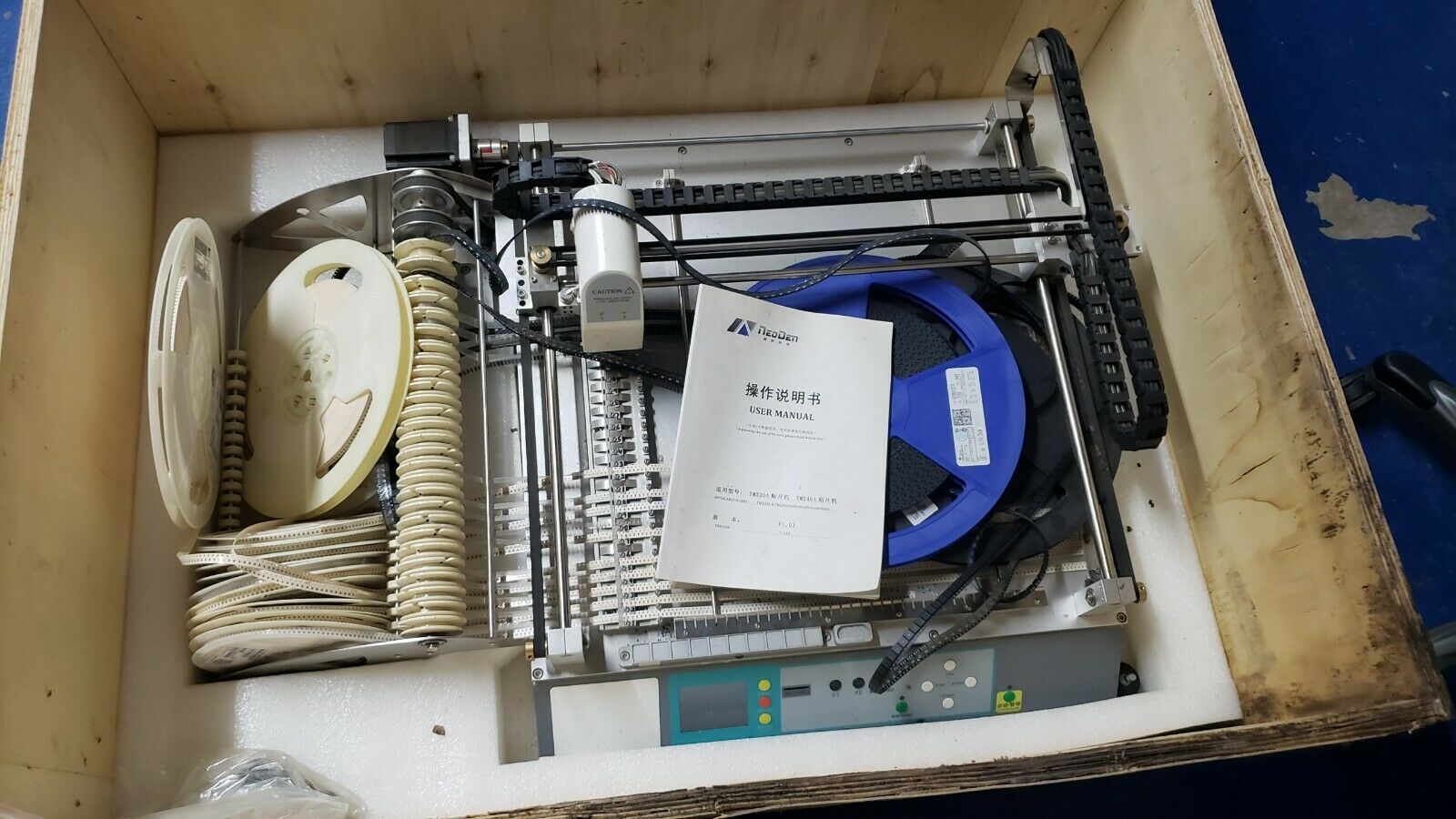

Small SMT pcb prototype assembly line with printer oven and pick n place machine

$ 3113.61

- Description

- Size Guide

Description

Small SMD pcb assembly line: Pick and place machine NeoDen YY1+ Manual stencil printer FP2636+ Reflow oven IN6 (without stand)

Applicable to: Education, personal pcba DIY, SMT labs or any other small budget start-up SMT line.

Machine support: 0201, BGA, QFP, Big aluminum capacitor, LED etc..

Standard tape feeder qty: 36x 8mm; 6x 12mm; 3x 16mm; Matched with vibration feeder, bulk feeder tray etc.

Product Parameters

Model Number

NeoDen YY1

Machine Style

Single Gantry With 2 Heads

Alignment

Vision & Vacuum

Placement Rate

Vision On

3000CPH

Vision Off

4000CPH

Feeder

Capacity you can setting in software

Tape Feeder: 52 (all 8mm)

Stick Feeder: 4

Flexible Feeder: 28------ for IC and cut tape and Stick feeder

Bulk Feeder: 19-------- for loosen bulk capacitors

Nozzle Change Capacity

3 Nozzles

Component Range

Smallest Size

0201

Largest Size

18x18mm

Max Height

12mm

Rotation

±180°

Placement Accuracy

±0.02mm

X-Y Repeatability

±0.02mm

Z-axis Max Movement Range

28mm

PCB Applicable Dimension(mm)

Maximum 249 x 350(dual sides tape feeder)

Maximum 315 x 350(single side tape feeder)

Electricity Supply

AC100V-240V

Software System

Independent Development

Control System

One-board Integration

Drives System

Stepper Motor

Positioning System

Fiducial Mark

PCB Handling

Manual PCB Loading/Unloading

Power

50W

External Dimensions(mm)

Machine Size

643(L)x554(W)x601(H)

Packing Size

700(L)x610(W)x595(H)(wooden box)

Weight

Net Weight

35.5kgs

Gross Weight

47kgs(wooden box)

Feature

1. Automatic nozzle changer help realizing nozzles changed flexibly

2. Supports bulk component feeder,strip feeder and IC tray feeder

1. Independent high-definition & high-speed dual vision recognition systems,as well as dual cameras for real-time display the working status

2. Newly designed software system & UI for visual programming and placement, which allows fast programming on the machine, friendly interface & easy operation

1. Linear rail design for X, Y axis to ensure accuracy and stability,and reduce noise at the same time

2.Patent-protected & new needle module is specially designed based on the linear rail with high reliability and durability

3.Comes with a high-definition capacitive touch screen, which can be adjusted up and down to meet the needs of different viewing angles and enhance the user experiences

4. Fully transparent acrylic covers with magnetic mode for a high level of ease of disassembly

Equipped with a vacuum detection function,can set standard vacuum detection values on placement head flexibly,all information can be displayed visually on the placement head

Packing list details:

Items

Spec

Remark

Unit

Q'ty

YY1 PnP Machine

set

1

AC Adapter

pcs

1

Tape Feeder

8mm

Includes Peeling Gadget

pcs

36

Tape Feeder

12mm

Includes Peeling Gadget

pcs

6

Tape Feeder

16mm

Includes Peeling Gadget

pcs

3

Stick Feeder

4 slots

set

1

Nozzle station

3 slots

pcs

1

IC Tray

Magnet

Matte Black

pcs

3

Strip Feeder Tray

8mm*3

pcs

1

Strip Feeder Tray

12mm+16mm

pcs

1

Positioning Strip

Magnet

Fix the Tray

pcs

5

PCB Fixation Needle

Magnet

pcs

3

Reel Holder Stand

350mm

Disassembled

set

1

Nozzle

CN040*2 CN065*2 CN100*1

CN140*1 CN220*1 CN400*1

pcs

8

SD Card

pcs

1

SD Card Reader

pcs

1

Double Sides Adhesive Tape

pcs

1

Marking paper

Approx 20 pages

pcs

1

Demo PCB

pcs

1

Manual stencil printer FP2636+ Reflow oven IN6:

Product Parameters

Model

FP2636- frame type

Max. pcb size

260*360mm

Max.Screen stencil size

260*360mm

Max. stencil frame size

400*500mm

PCB thickness

0.5-10mm

Positioning pin size

1mm/1.5mm/2.0mm/2.5mm/3mm (selectable)

Positioning mode

outside positioning holes

Repeatability

+/-0.01mm

Platform height

190mm

Fine adjustment range

Z-axis:+/-15mm

X-axis:+/-15mm

Y-axis:+/-15mm

Max. rotation angle

+/-15 angle

Machine dimension

594*382*187mm

Packing dimension

660*470*245mm

N.W./G.W.

11/13kg

Model

IN6 Reflow oven

Power max.

2KW

Heating zone quantity

upper3/down3

Conveyor speed

15 - 60 cm/min (6 - 23 inch/min)

Standard Max Height

26mm

Temperature control range

Room temperature

~

300 degree celsius

Temperature control accuracy

±0.2 degree celsius

Temperature distribution deviation

±1 degree celsius

Soldering width

260 mm (10 inch)

Length process chamber

680 mm (26.8 inch)

Heat-up time

approx. 15 min

Dimensions

1020 x 507 x 350 mm (L x W x H)

Packing Size

112x 62x 56cm

N.W.

49KG

Reflow oven features

1.Full heat convection, excellent soldering performance.

2.16 working files can be stored, flexibly convert from Celsius to Fahrenheit, easy to understand

3.Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2ºC.

4.Built-in welding smoke filtering system, elegant appearance and eco-friendly.

5.High-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature deviation is less than 2ºC.

6.Heat insulation protection design, the casing temperature can be controlled within 40ºC.

7.Equipped with an ESD tray, easy to collect PCB after reflowing, convenient for prototype.

8.6 temperature zones, light and compact.

9.PCB soldering temperature curve can be displayed based on real-time measurement

10.Approved by TUV NORD CE, qualified and reliable.

Payment&Delivery:

1) Payment method: Wire transfer, Paypal.

2) The default delivery method is via FedEx/ DHL(door to door), unless specific requirement from customer.

3) Delivery time: 7working days.

Warranty:

The guarantee period is 2 years from the time of purchase and lifelong service support as well as a long-term factory price supply. NeoDen will provide online Q/A and troubleshooting support and technical advice service. Fe

el free contact to me(

joyce_10241

)if have more questions,tks.